Building a Quattro 16

by Peter Williams From-Maltese Boats and Yachting Magazine,May 1994

One of the cheapest and most cost effective ways of owning your own small sailing boat is to build it yourself! I know that the thought of building a boat immediately puts a lot of people off, thinking that the complete scope of tooling up, lines plans and actually building their own boat is a task only for trained people with vast experience. Well, I have now actually built two small sailing boats which have proved themselves and yet before I started, I really thought that I was treading in an area which I should leave to the experienced boat builder.

The particular boat which I would like to tell you about is a very new design catamaran from the board of the world-famous designer Richard Woods. It is a 16 foot twin trapeze racing catamaran called THE QUATTRO which has a rotating mast, fully battened main sail, the jib being fastened to the forestay by an ingenious zip method. The control lines are laid out so well that all sail adjustments can be made while helm and crew are out on the trapeze. The main is controlled using two triple blocks giving 7 to 1 purchase and the jib sheet is also run on a double block mechanism thereby giving the crew an easy time with a 3 to 1 advantage. All blocks fitted are hi-tech, full ball bearing type with ratchet fittings for the main control lines.

The tillers are of the Akerman type, IYE equipment being specified by design, but to save money plans are available to build your own. The mast is completely sealed so that when the boat tips over, it does not pass through the 90' position as the mast floats.

The boat has three crossbeams, contrary to popular belief that the front crossbeam can add to factors leading to the boat pitch-poling, many hours of testing in wind tunnels have proved this theory wrong. In fact, the addition of a front cross beam stiffens the boat up completely and helps prevent the two hulls being pulled out of alignment when everything is sheeted in tightly. The superb design of this boat actually gives the boat lots of lift in the bow area to help prevent the bow dipping under a big wave. One final unusual item on this boat is the skegs on both hulls, which eliminates the need for dagger boards thereby making sailing and beaching much easier. The skegs are very long and quite deep which adds to the very good up windward performance of this craft.

The proof that not only is the design of this boat second to none, the plans are so simple and easy to follow that two Quattros have been built by inexperienced people here in Malta and succeeded in finishing first and second in last year's (1993) Malta National Sailing Championships in the Handicap Class, a class which is very much favoured to small lightweight dinghies and not catamarans due to the very gentle summer breezes which are so common in Malta.

The building of this boat only takes about 100 hours, short enough to build over the winter when many sailors do not sail. There are no special tools required. The only serious tools required which would not be found in every household toolbox is a jigsaw and a planer. I must at this point emphasise that the boat is not built from a kit but from actual plans thereby making the boat even cheaper to build. The total materials required to complete the job are 7 sheets of 4mm ply, 1 sheet of 12mm, 5 - 7 kgs of Epoxy Resin and enough cloth to sheath the boat to give additional strength.

The first thing is to join 2 sheets of ply together to get the 16 feet length of the boat. The two outer edges of the ply become the gunwales and the shape of the keel is then drawn onto this joined ply. After cutting the correct shape the 2 halves of the boat are joined together using the most simple of all building methods - stitch and glue. The great advantage of this building method is that after 4 or 5 hours work, you end up with a shape which actually looks like a boat. This gives the builder a psychological push to complete the boat as he can see definite rewards after such little effort.

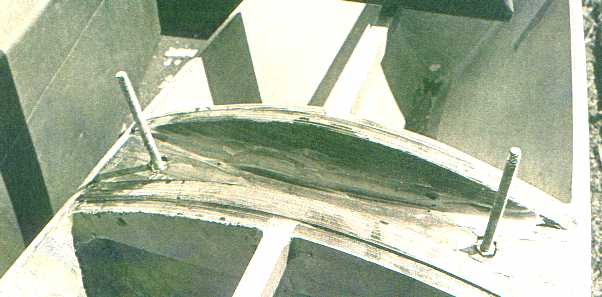

The next task is to cut out the bulkheads. Due to the small size of the boat, this task is completed simply and easily. The bulkheads are then inserted, "sewn" in place, and finally glued. Once again, the stitch and glue method is used to hold the bulkheads in place until the glue has cured. Then two "beam boxes" are made. These are the reinforced areas where the two main cross beams which hold the two hulls together will be attached once the boat is completed.

Once this stage is reached the second hull is brought to the same state and then the two main cross beams are fitted to align the two hulls. At the same time the two skegs are fitted simultaneously and once this is completed both the hulls are sheathed with cloth and epoxy. The longest job of all is the sanding and filling to achieve a good finish. I was extremely careful when I reached this stage and now most people think that I own a fibreglass boat as the finish on the hulls is to as high a standard as most factory new GRP boats. The two hulls are then dismantled from the main cross beams and turned over so that the decks can be fitted. Some of the fittings are installed before decking, for example the chain plates and rudder fittings, and once the decks are completed the final job is to fit the front cross beam, and there you have a very easy to build, fast and successful racing catamaran.

A question I'm asked many times is why build out of wood. The answer is simple - the weight to strength ratio of wood is by far better than any other cheap building method, especially GRP. This 16 foot racing cat can be easily hand carried by 2 adults when the boat is fully rigged - just try doing that on your Dart.